The flexibility of expansion connectors pays off when conductors are subjected to powerful forces.

Expansion connectors

Expansion connectors

Expansion Connectors

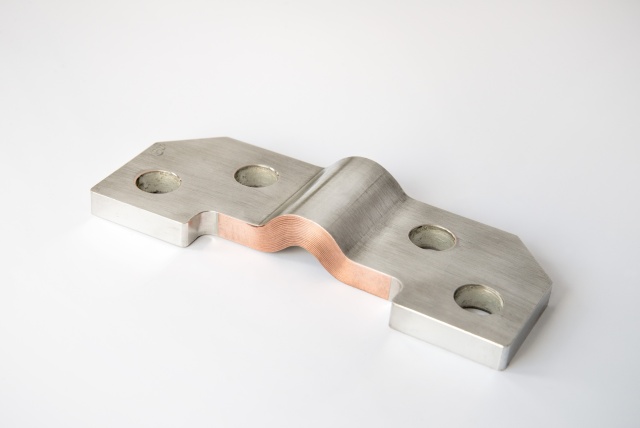

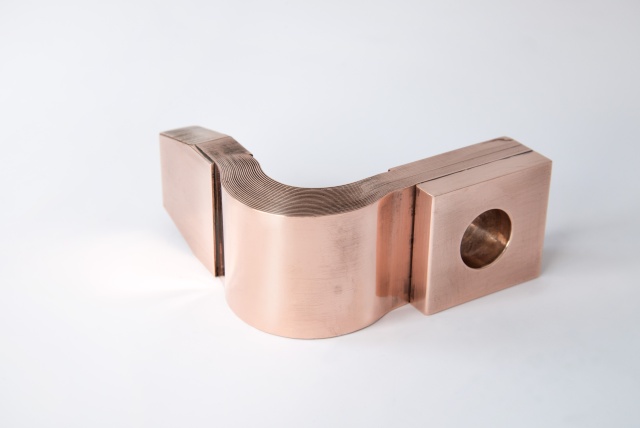

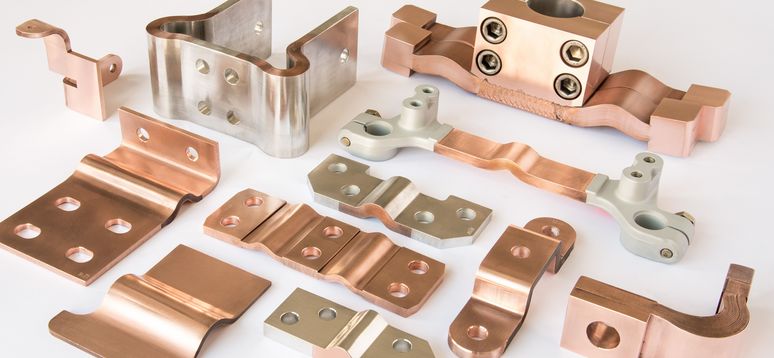

Expansion connectors, also known as expansion straps, are flexible connecting elements designed for power transmission, ensuring reliable electrical connections even under challenging conditions.

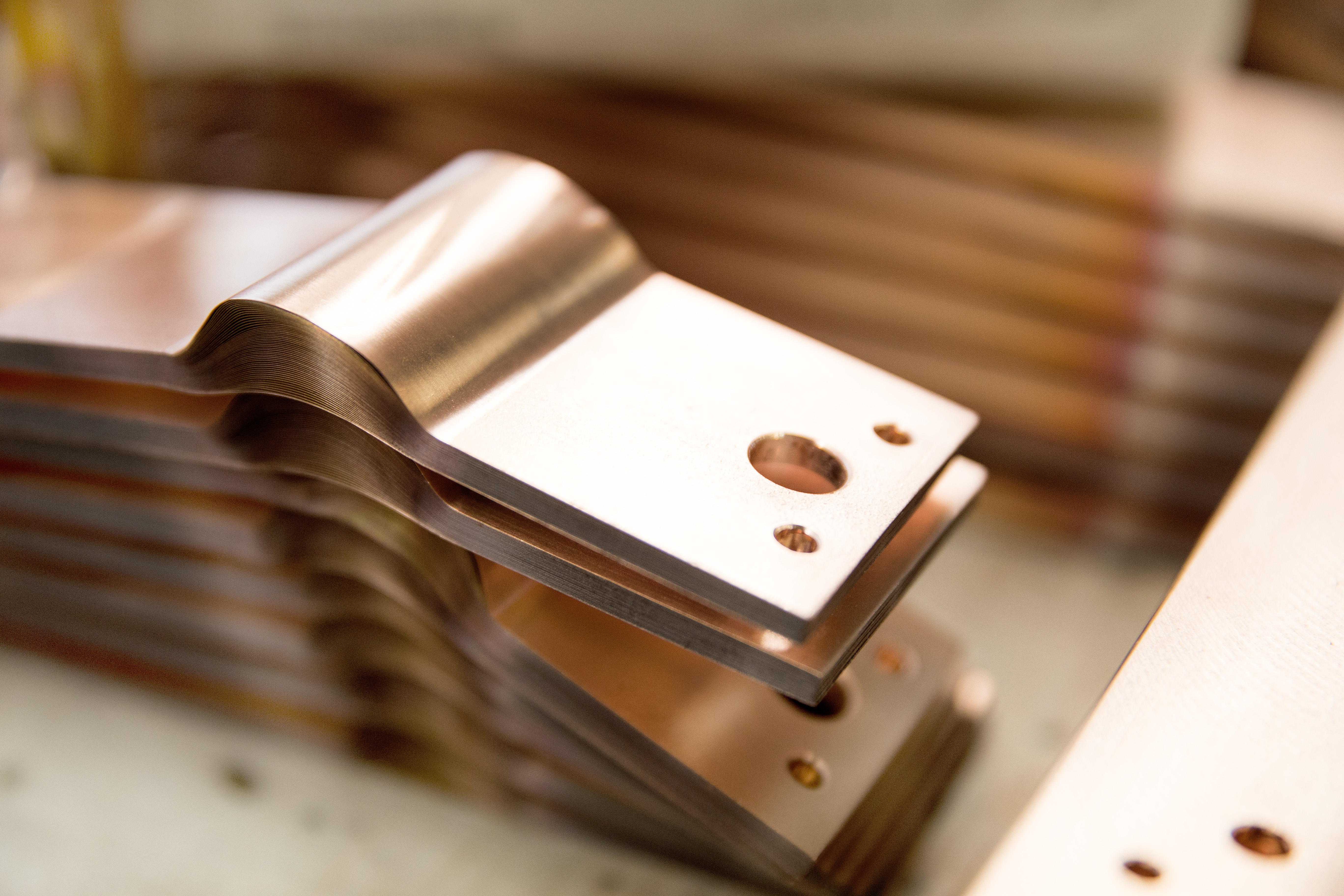

Copper Expansion Tapes

Copper expansion tapes (also referred to as laminated strips) are composed of thin copper foils stacked on top of each other. Various types of pure copper can be used, with Cu-ETP (formerly: E-Cu58, E-Cu57, E-Cu), which has a copper content of 99.9%, being a standard material available in many thicknesses (0.1 to 0.5 mm).

If needed, we also use oxygen-free copper grades such as Cu-OF, Cu-OFE, Cu-PHC, and Cu-HCP. Additionally, we have experience working with low-alloyed copper materials like CuCrZr and CuAg. The ends of the tapes are press-welded or, upon request, brazed, and processed according to customer-specific requirements. The connection between flexible components can also be achieved using the TIG welding process.

We are certified for welded joints in the railway sector according to EN 15085. Depending on customer requirements, the surface can be left untreated or coated with silver, tin, or nickel.

Aluminum Expansion Tapes

Aluminum expansion tapes (also known as lamella tapes) consist of thin aluminum foils stacked on top of each other. For the flexible part, we use pure aluminum EN AW-1050 - Al 99.5 or EN AW-1350 - E-Al 99.5 with a thickness of 0.5 mm. For the connecting brackets, we use EN AW-6082, EN AW-6060, or EN AW-6101, subject to agreement.

The connection brackets and flexible parts are welded using MIG, MAG, or TIG processes, depending on the application and size. We are certified for welding connections in the railway sector in accordance with EN 15085. The connecting straps are machined according to customer specifications and can be coated with silver or nickel if required.

Applications and Advantages

The flexibility of expansion straps offers significant advantages wherever strong external forces impact the conductor, such as switching surges, oscillations, or vibrations, or in situations where devices and machines cannot be rigidly connected. Expansion straps effectively compensate for thermal expansion as well as installation tolerances during assembly.

Expansion straps are widely used in mechanical and plant engineering, power generation, and vehicle technology, including:

- in machines, transformers, and generators

- in welding systems and switchgear

- between busbars

- between busbars and switchgear

- between motors and machine parts

We always develop our solutions in close collaboration with our customers, tailoring them to specific needs when necessary. As classic problem solvers, we offer support from the planning and project planning phases, providing advice and assistance as needed. Take advantage of our services or contact us for more information without obligation.