CL1 certified welding solutions, also for aluminum

Welding-Solutions

Welding-Solutions

Welding Technology at Sefag Components AG

Sefag Components AG is certified according to EN 15085-2 (CL1), ensuring the highest quality standards in rail vehicle construction.

Further information on certification: EN 15085

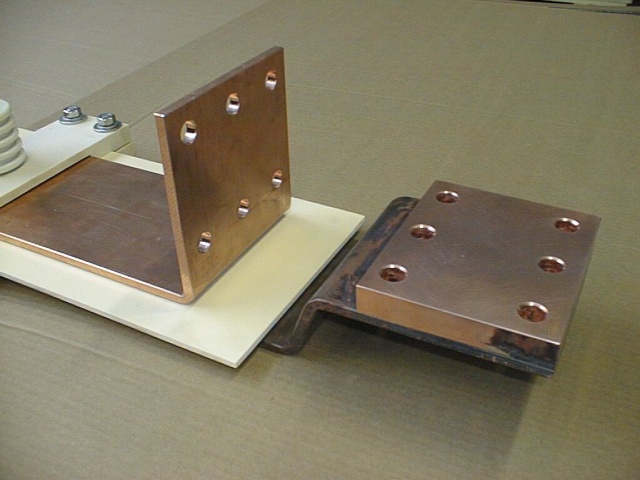

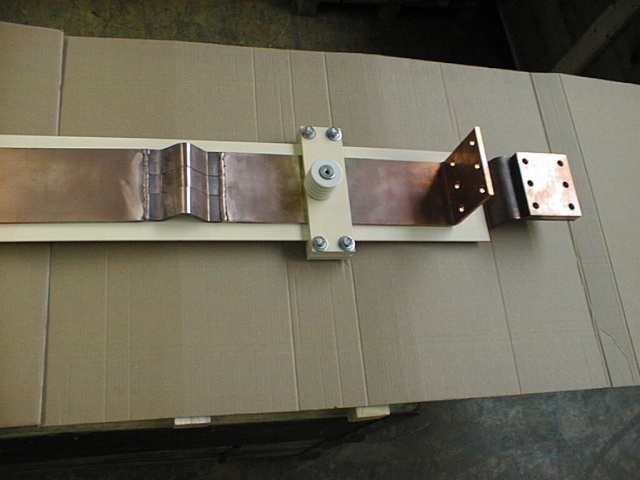

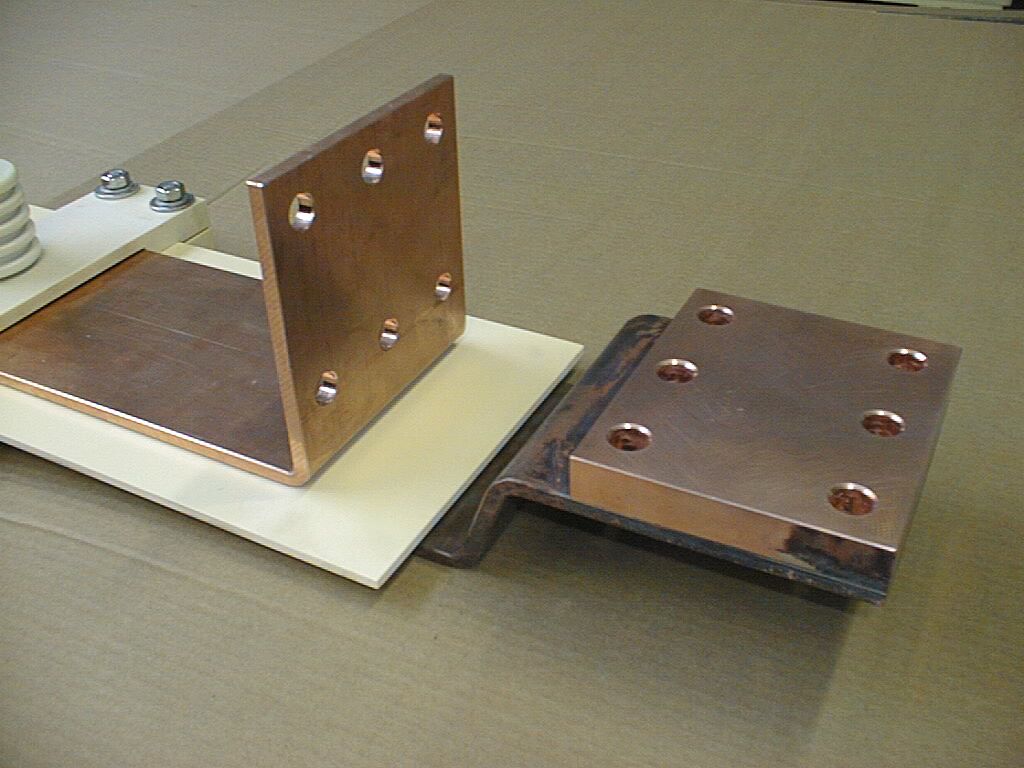

We specialize in welding copper and aluminum joints in the field of vehicle construction, particularly for rail vehicles, using the TIG (Tungsten Inert Gas) process. Whether the goal is to ensure electrical conductivity or to create a robust mechanical connection, our welded joints deliver both.

In addition to the welding applications mentioned above, we have extensive experience in welding busbars and busbar systems made of copper and aluminum, which are widely used in mechanical and plant engineering.

Our Welding Processes and Materials:

- Copper (Cu): TIG

- Aluminum (Al): TIG, MAG

- Chrome Steel (Cr.St.): TIG, MAG

- Steel: TIG, MAG

We also leverage our extensive expertise in brazing to provide you with the best possible solution for your needs.

You can rely on our expertise in welding technology—precise, reliable, and powerful!